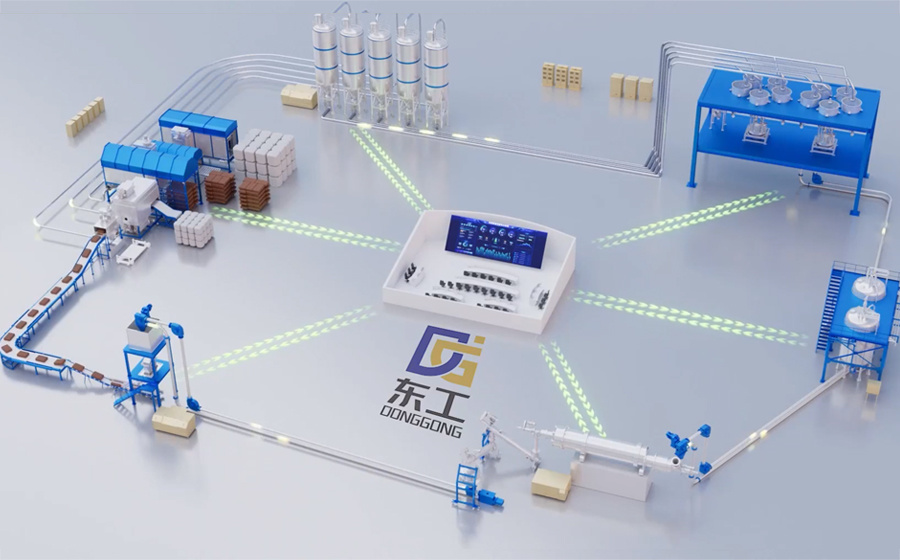

DONGGONG AUTOMATION EQUIPMENT

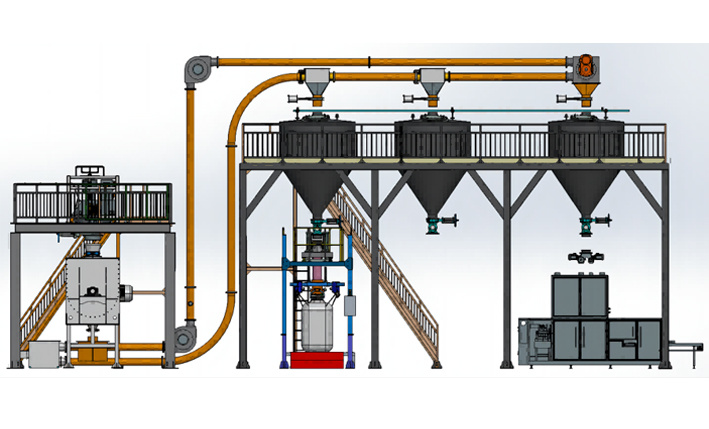

A national high-tech enterprise focusing on the research and development, design, manufacturing, sales and service of complete sets of powder and granule system equipment, is a domestic professional transportation equipment manufacturer. It provides complete sets of equipment and solutions for new energy, fine chemicals, food processing, new chemical materials, environmental protection, smelting, medicine, chemicals, building materials and many other fields. We have been adhering to the enterprise spirit of "responsibility, responsibility and integrity", and are committed to the research of powder particle complete system equipment technology and strive to provide cost-effective solutions for high-quality customers in a wide range of fields.

-

R&D Innovation

-

Intelligent manufacturing

-

Engineering case

28

Jul 28,2024

2024

30

Aug 30,2022

2022

What are the advantages of pneumatic conveying system equipment?

22

Aug 22,2022

2022

PRODUCT SOLUTIONS