Positive pressure dense phase conveying

Dense phase conveying is also called sending tank or bin pump conveying. The conveying method uses gas pressure higher than 1kg and positive pressure to push materials through conveying pipelines, so it is often called high pressure system. The material gas ratio of the system is very high. The initial speed of this system is about 2 m/min starting speed, at the end of the higher about 20 m/s (except for full load transport), the pressure of the delivery pipeline is generally 2~3kg, at the end of the system pressure is almost zero. The system uses an air compressor as the power source, which is characterized by low conveying speed and less impact on the quality of the material.

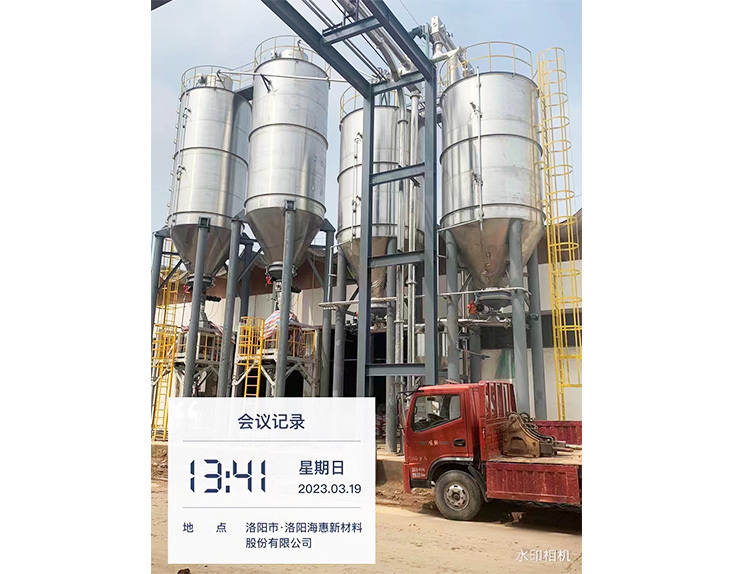

After the material is unloaded, it is transported to the silo through pipe chain transportation or pneumatic transportation for solid-gas separation. The material enters the silo, and the gas with dust is filtered by the dust collector and discharged into the atmosphere.

Century era negative pressure conveying

The negative pressure dilute phase conveying system adopts negative pressure Roots pump power source, the pipeline conveying pressure is in a low vacuum state, the pipeline wind speed is about 10-35m/sec, and the material is misty in the pipeline. The starting pressure of negative pressure conveying is equal to or close to atmospheric pressure, and the end pressure is between -10 and ~ 50Kpa, and the vacuum degree of the pipeline gradually increases along the conveying pipeline. Negative pressure dilute phase conveying system is also called vacuum dilute phase conveying system.