Products

Weighing batching system

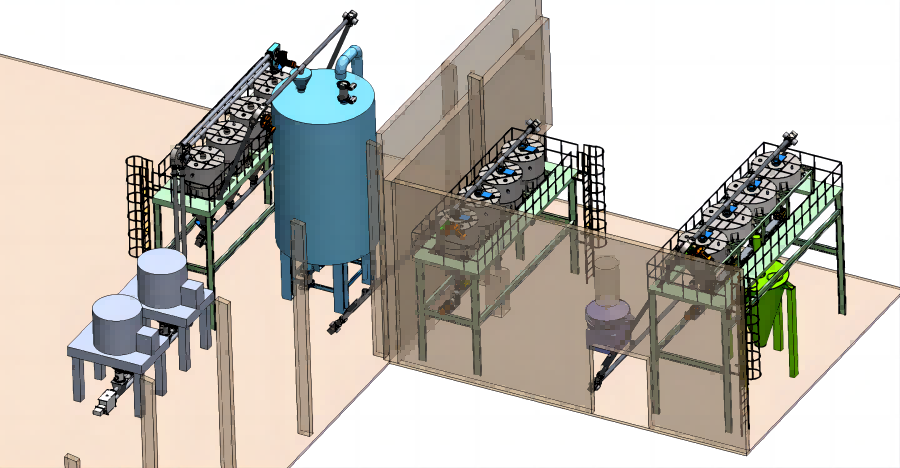

The automatic weighing control system integrates control technology, weighing measurement technology, sensor technology and computer application technology. It has the advantages of digital display of weight value, high control precision and convenient data transmission. It adopts common control mode, strong compatibility and common data interface, such as RS485 or Ethernet, which can be connected to local area network and can realize integration of management and control, has been widely used in chemical, building materials, feed, metallurgy, food and other industries.

Used for single weighing and metering, or quantitative batching of multiple materials;

System features

1. High precision and high reliability

2. Professional material handling ability

3. Friendly man-machine interface

Weighing control system, according to the actual process of the process to dynamically reflect the material, storage, ingredients and related equipment working status and parameters, the formation of "distributed control" or "centralized control" two systems, greatly increasing the reliability of the system. Provide a variety of equipment including raw material storage, transportation, weighing ingredients, dust removal, material mixing, weighing packaging, etc., involving powder, solid bulk, liquid and other materials.

System Description

Weighing batching system can be based on the production process requirements, specific material characteristics, reasonable selection of incremental method, reduction method, weightlessness and other weighing methods, complete batch batching or continuous uninterrupted feeding, with single bucket single material, single bucket multi-material, multi-bucket multi-material and their combinations and other working modes.

1. Realize the function of manual operation and automatic control of ingredients;

2. Dynamic simulation of the production process, which can display the real-time working status and the target weight, actual weight and error value of each material;

3. Preset the storage formula, which can be called, modified, deleted and queried at any time;

4. The historical record of each batch of ingredient data is kept, and the output and consumption of materials can be counted, queried and printed at any time;

5. In the process of batching, it has automatic alarm for material shortage, and can manually replace the warehouse number with the same material online;

6. With operator rights management, on-site management and network remote services and other functions;

7. Imported industrial computer (IPC) is used as the upper computer monitoring system, with Kingview6.51 monitoring configuration software to ensure the stability, reliability and long-term nature of the system.

8. The whole system is man-machine dialogue mode, easy to operate and easy to use, easy to maintain;

9. The use of frequency converter to control the blanking can improve the accuracy of the ingredients, thereby improving the quality and stability of the product.

Once the enterprise adopts the automatic weighing batching system. Significantly reduce labor, reduce labor intensity, ensure the reliability and safety of production, reduce production costs, reduce environmental pollution, improve product quality and economic benefits.

| Industry classification | Common Materials |

| Petrochemical, plastics | PP (polypropylene)/ PE-LLDPE-LDPE-HDPE (polyethylene)/ PC (polycarbonate)/ PVC (polyvinyl chloride)/ PS (polystyrene)/ PA (polyamide)/ PET (polyester)/ ABS (acrylonitrile-butadiene-styrene copolymer)/ PTA/CTA (purified terephthalic acid)/ EVA (polyethylene-vinyl acetate)/ MELAMINA (melamine) |

| chemical industry | Calcium carbonate/sodium carbonate/sodium hydroxide/dolomite/titanium dioxide/barium sulfate/zinc oxide/starch/kaolin/talc/fatty acid/stabilizer (lead/zinc)/alumina/emery/glass frit/lime/sand/clay/dry ooze/polyester/resin/dissolving agent/kiln/titanium dioxide |

| rubber industry | Polymer/Carbon Black/Silicon/Deposited Silicon/White Filler/Micro Ingredients/Rubber Compounds |

| Plastic industry | Petrochemical raw materials/filler calcium carbonate, kaolin, chalk/stabilized artificial rubber lead, calcium, zinc, tin/processing aid pigment/titanium oxide/lubricant/plasticizer DOP, DIDP, ESO/plastic particles |

| Food/Pharmaceutical Industry | Rice food/rice flour/flour/semolina/wheat bran/wheat flour/crystal sugar, crystal sugar/milk powder/starch/malt/glucose/cocoa beans/coffee beans/peanuts/black beans/vegetable oil, fat/citric acid/salt and additives |

| Electric power/metallurgical industry | Fly Ash/Desulfurization Ash/Dedusting Ash/Slag/Copper Powder/Iron Powder/Aluminum Powder |

| building materials industry | Cement/Sand/Stone/Fly Ash |

Related Products

Weighing batching system

Weighing batching system

Weighing batching system