Products

Airflow mixing

Overview

1. Airflow type non-destructive particle, powder automatic operation mixing equipment

2. No dead angle, no leakage, sealed mixed environmental protection type

3. No passive pollution, no large mechanical parts maintenance costs.

4. Quick mixer (just a few minutes to mix)

5. Large-capacity mixer, homogenization bin (dozens of tons or even larger at a time, homogenization mixing equipment)

Detailed Description

1. Airflow type non-destructive particle, powder automatic operation mixing equipment

2. No dead angle, no leakage, sealed mixed environmental protection type

3. No passive pollution, no large mechanical parts maintenance costs.

4. Quick mixer (just a few minutes to mix)

5. Large-capacity mixer, homogenization bin (dozens of tons or even larger at a time, homogenization mixing equipment)

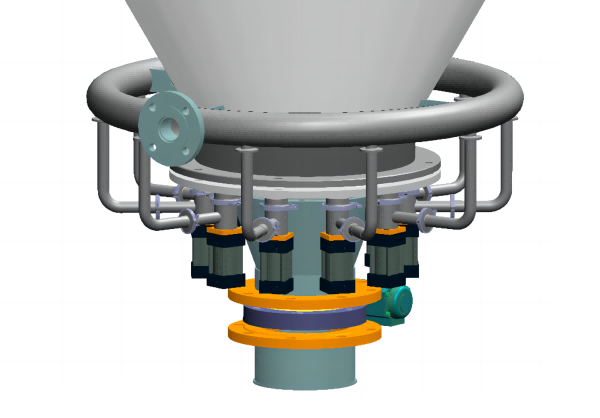

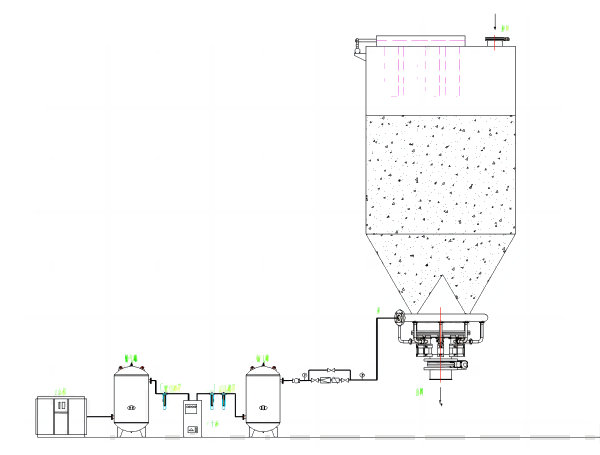

Principle

When the air at the bottom of the mixer is injected instantaneously, the powder particles in the can become boiling and begin to be fully stirred and mixed. The injected air is discharged from the air filter above. Spray a very short time and consume little compressed air, will be able to fully mix and efficient homogenization. Combined with raw material conveying, the introduction of touch screen and PLC control, it is convenient to set up the automatic processing production line of raw materials.

Features

1. Quick mix large capacity

It only takes a few minutes for a batch of materials to be mixed evenly, and it is from a few tons to dozens of tons at a time, and it saves the mixing operation cost.

2. No dead angle design

No concave round hole, yin angle residue, etc., can be applied to medicine, food, etc.

3. No mechanical rotating parts in the mixer

There is no frictional heat generation and there is no contamination of the product by the lubricant. Because there is no agitation, it can be mixed without damage, such as chicken essence, compound fertilizer particles, etc. Especially suitable for the mixing of micro powder, will not jam rotating machinery such as bearings, etc., long trouble-free time.

4. Closed mixing, no dust environmental protection type

5. Simple to use, free to set, automatic operation.

6. convenient feeding and discharging.

Application occasions

This equipment is mainly used in chemical products, plastics, pharmaceuticals, electronic substrates, food, feed, cement, earth, ceramic raw materials and other industries have homogeneous requirements, fast and large capacity mixing occasions.

Related Products

Airflow mixing

Airflow mixing

Airflow mixing

Gravity mixing bin

Gravity mixing bin