Related technologies of material and wet material collection after centrifuge

Release time:

2021/09/09

How to solve the automatic conveying of materials after centrifuge dehydration?

The conveying mode of the material after dehydration of the centrifuge can be used, such as: pipe chain conveyor, screw conveyor, belt conveyor or manual handling and other conveying methods.

First of all, according to the demand side of their own process to choose the way of dehydration centrifuge. Chemical industry commonly used centrifuge has the following:

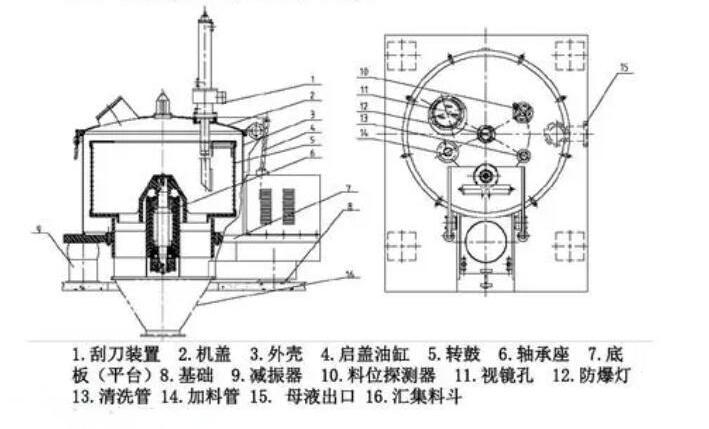

1. Vertical scraper centrifuge

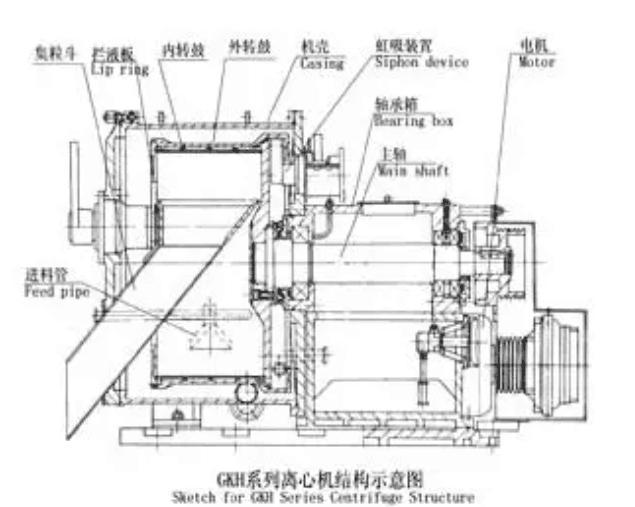

2. Horizontal scraper centrifuge

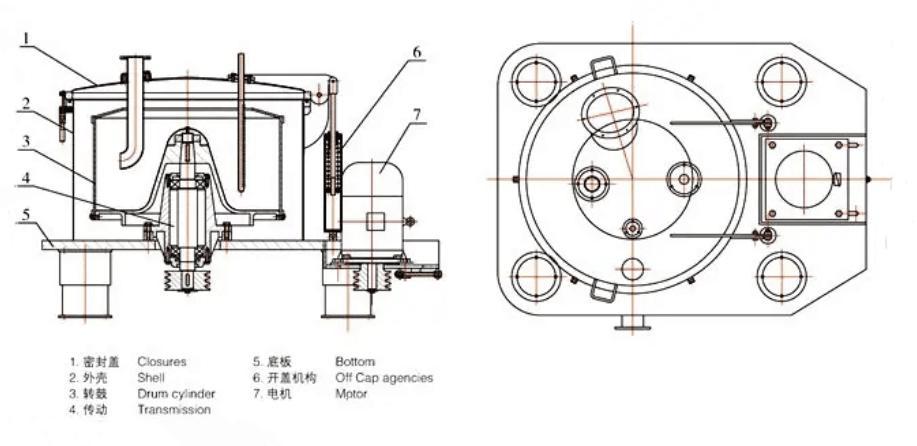

3. Pull bag centrifuge

At present, under the premise that China advocates energy conservation and environmental protection, safe production but labor shortage, how to solve the automatic transportation of materials after dehydration of the above three centrifuges has become the most concerned problem in chemical industry, medicine, new materials, agriculture and other major industries. At this time, Ferguson Conveying Machinery (Changzhou) Co., Ltd. (Sun Zong: 13515269469) has achieved impressive results in solving the problem of automatic transportation of materials after dehydration by centrifuges.

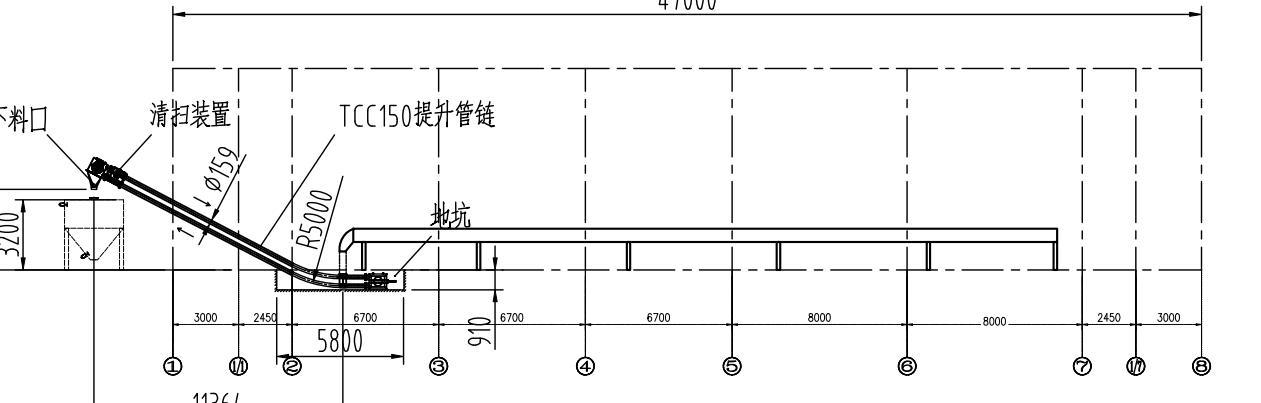

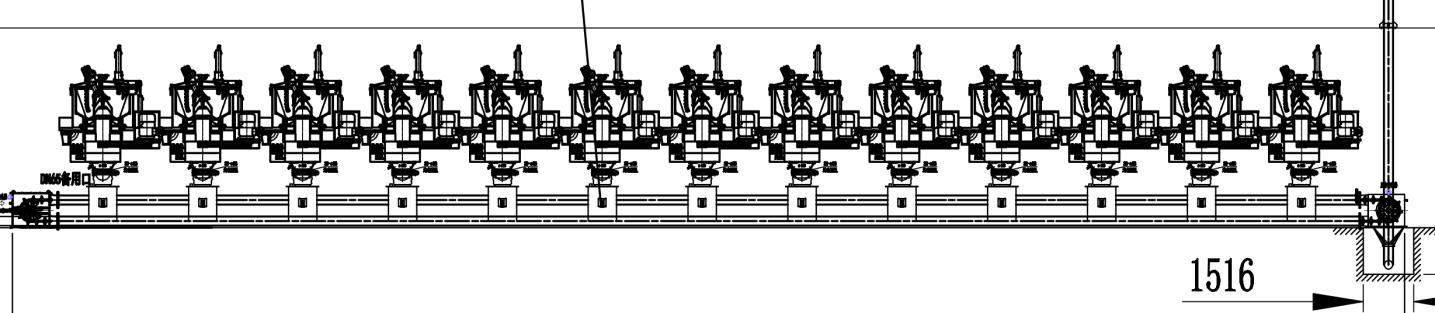

Therefore, the company decided to sort out our results and share them with other industries or peer enterprises in need. When 1. choose a vertical scraper centrifuge, the user is based on their own capacity to match the corresponding number of machines, generally 2, 15 or more. In order to realize automatic production and the appearance of the operation site, the arrangement of the centrifuges can be arranged in rows or in a rectangular manner. The water content of the material after dehydration is determined by the batch time and equipment capacity (generally between 3% and 15%), so the problems of the centrifuge equipment itself, or improper operation and other problems will cause the mother liquor to flow to the lower equipment. If the mother liquor contains flammable, explosive and toxic gases, it is necessary to consider the closed transport.

When the 2. chooses a horizontal scraper centrifuge, the user can choose 1 or 10 pieces of equipment according to the workshop height and process requirements, and arrange them in a font. When choosing this centrifuge, the height of the discharge port must be taken into account in the preliminary design, and the subsequent automatic transportation can be docked. The transformation of many projects is mostly limited by the height of the ground. After the material is dehydrated, the material in the centrifuge is sometimes caked due to the change of moisture content. If the mother liquor contains flammable, explosive and toxic gases, it is necessary to consider the closed transport.

When 3. choose to pull bag centrifuge, because of environmental protection, labor shortage, market demand is small, the user choice of such equipment has been reduced year by year. However, due to special process requirements, or from the input cost considerations, there are still enterprises will choose to pull the bag centrifuge dehydration method, high efficiency, large capacity. However, the follow-up material transportation of this centrifuge is mostly handled manually by buckets, so it can only be applied to countries and regions with low labor costs and low environmental protection requirements. How to solve the automatic conveying of centrifuge materials after dehydration, and what kind of conveying method to choose has become a big problem for users. However, if you choose to consult Ferguson Conveying Machinery (Changzhou) Co., Ltd. (Sun Zong: 13515269469), the company will recommend you with different conveying equipment according to the actual situation of users. According to the advantages and disadvantages of various conveying methods, the following conveying methods are generally recommend: 1. The conveying method is simple and the equipment investment cost is low, but the disadvantages are that the conveying site environment is dirty and messy, the mother liquor emits pungent smell, choking nose and hot eyes, and long-term working in this environment will seriously endanger human health. Under the environmental protection concept policy that the demographic dividend is about to disappear, and President Xi strongly advocates that "green water and green mountains are golden mountains and silver mountains", this mode of transmission is extremely undesirable.

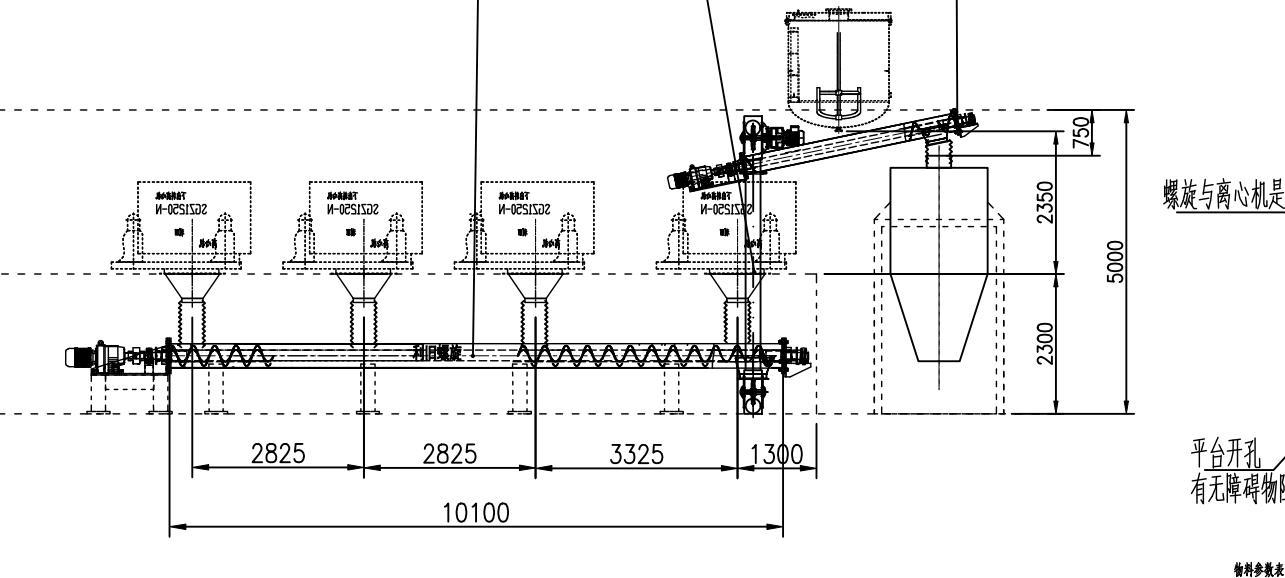

2. The screw conveyor collects the mature conveying mode and the layout is simple. However, the disadvantages are: poor sealing, high moisture content, strong material viscosity, will block the material, will be on the spiral main shaft, between the blades, and the conveying distance is limited, the layout is not flexible, the residual amount in the spiral main shaft is large. For this kind of conveying method, it can generally be used for separate centrifuges or conveying projects with high floors.

3. Belt conveyor This conveying method is the same as spiral conveying, mature and stable, longer than spiral conveying distance. However, the disadvantages are that the sealing performance is poor, the discharge of mother liquor and the explosion-proof nitrogen filling cannot be handled, and the conveying environment is even worse than that of the silo. Therefore, almost no enterprise has chosen this conveying method.

4, pipe chain conveyor to collect this kind of conveying mode is the first choice of the vast majority of customers. The advantages of this method are: the equipment runs smoothly, flexibly, and has a long conveying distance, which can better solve the problems of airtightness, explosion-proof, nitrogen filling, and non-blocking materials in the process of material collection and transportation.

Ferguson Conveying Machinery (Changzhou) Co., Ltd. was established in 2014. It is a professional enterprise specializing in powder material unpacking, conveying, measuring ingredients and centrifugal material collection. As of the end of July 2021, the company has 85 employees, including 25 professional and technical personnel with bachelor's degree or above, 48 production personnel, and all kinds of professional production equipment. The company adheres to the excellent material handling concept and technology, and adheres to the service concept of professionalism, dedication and precision for more than 10 years, providing users with sincere service and the world's most cost-effective material handling system.

Company address: No.58 Songtao Road, Zhonglou District, Changzhou City, Jiangsu Province,

Contact person: Mr. sun tel: 13515269469

Website: www.czfgs.com E-mail: 2851677050@qq.com

Previous Page

Next Page

Previous Page

Next Page