Products

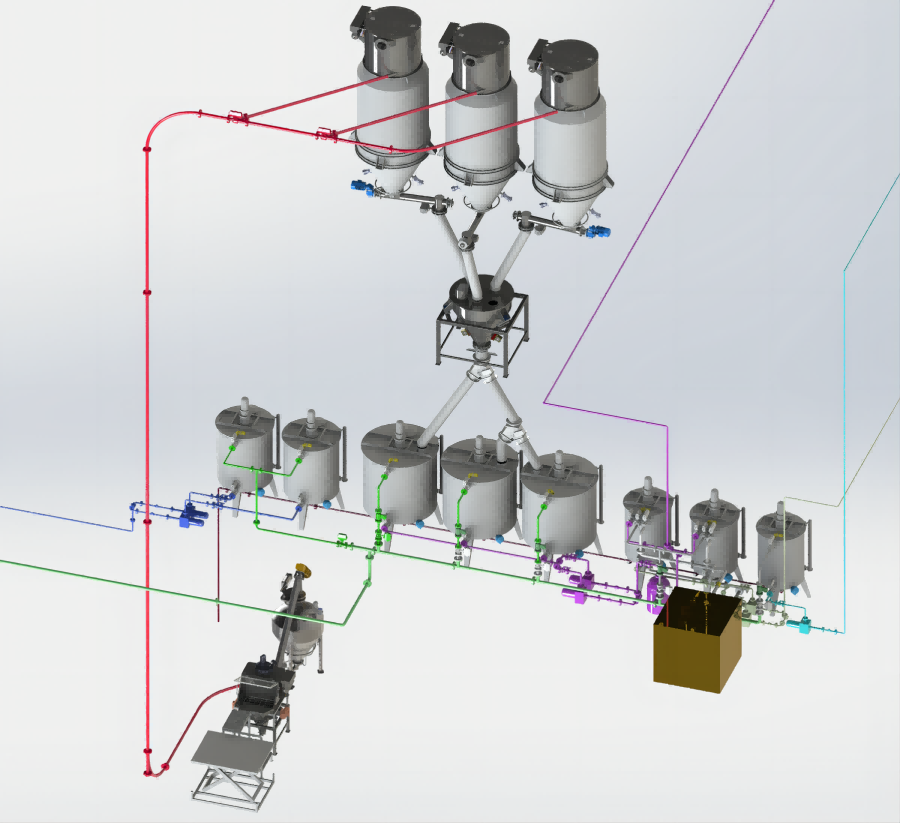

Positive pressure dense phase conveying

Positive pressure dense phase conveying is also called sending tank or bin pump conveying. The conveying method uses gas pressure higher than 1kg and uses positive pressure to push materials through conveying pipelines, so it is often called high pressure system. The material-gas ratio of the system is very high. The initial speed of this system is about 2 m/min of the starting speed, at the end of the higher about 20 m/s (except for full-load transport), the pressure of the delivery pipeline is generally 2~3kg, at the end of the system pressure is almost zero. The system uses an air compressor as the power source, which is characterized by low conveying speed and less impact on material quality.

At present, the use of high-pressure dense phase system has been very extensive, at the same time for different conveying materials can choose different conveying methods, in order to maximize its performance and efficiency, reflecting its economy.

There are two modes of delivery tank: delivery tank (bin pump) positive pressure dense phase delivery and delivery tank combination full load delivery. Each kind of material of the user has certain particularity and pertinence. Our different conveying systems also have different operation performance and use characteristics. According to different requirements, we provide the best operation scheme and integrated system that meet the production process and material requirements of the user, so as to ensure that the user's material can meet the best conveying requirements and improve production efficiency.

Features

1. The conveying speed is low, which has little effect on the quality of the material.

2. Less gas consumption, the system terminal of the material and gas separation is relatively easy.

3. The system has higher pressure, lower flow rate but large conveying capacity.

4. The equipment is simple, the area is small, and the space can even be fully utilized, and the investment and maintenance costs of the equipment are low.

5. Large amount of transportation, fewer operators are required, and full automation of unmanned management can be realized, so less labor costs are required.

6. The transported materials are not affected by the climate and the surrounding conditions of the pipeline layout, and the layout of the production workshop is relatively easy.

The pipeline can be flexibly arranged, so that the configuration of plant equipment is more reasonable.

Related Products

Positive pressure dense phase conveying

Positive pressure dense phase conveying

Positive pressure dense phase conveying