Products

Automatic unpacking of small bags

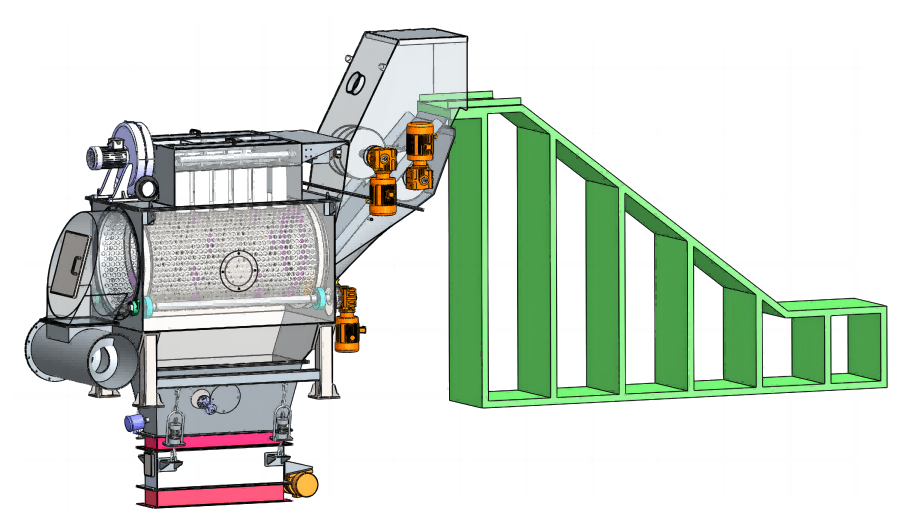

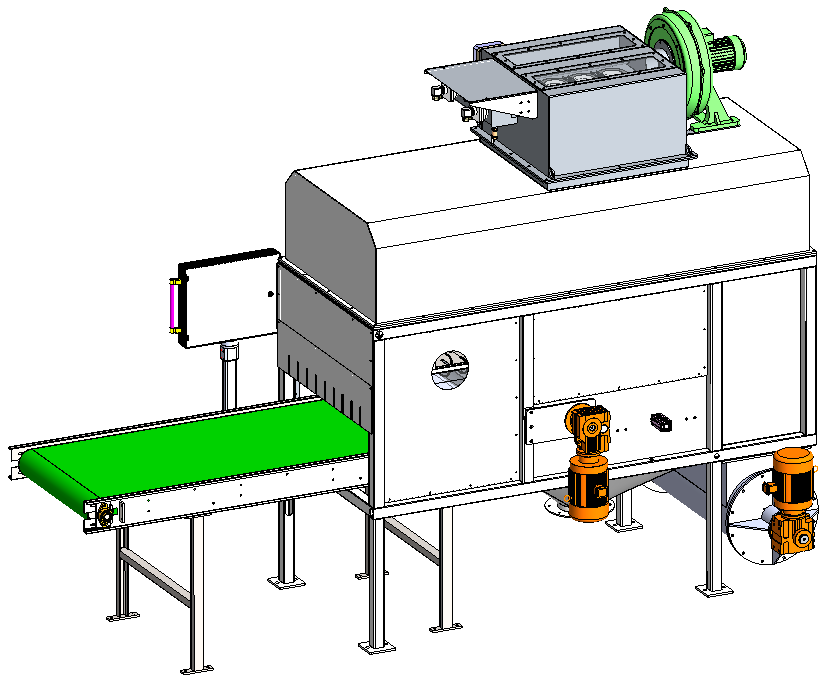

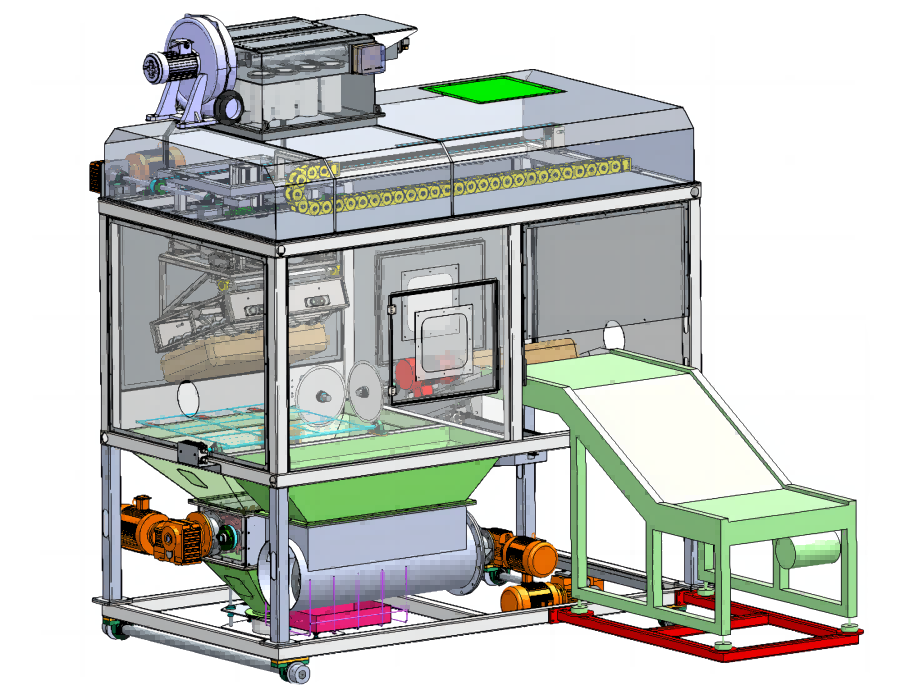

The small bag automatic unpacking machine is also called the small bag automatic dust-free feeding station, which means that the whole production process only needs to put the small bag packaging materials on the conveyor belt, and the rest is automatically carried out by the unpacking machine. During the whole unpacking process, the filter and dust removal fan carry out dust removal, and the dust will not leak out. It is suitable for 10-50KG small bag packaging powder and particle materials. It can comprehensively control the dust during the pouring process.

The dust-free pouring station equipment is a set of combination. The automatic unpacking machine consists of seven parts: belt conveyor, cutter device, drum screen, intermediate support, bag dust collector, screw conveyor and control box. The dust raised during unpacking is collected by the fan, and the dust is filtered and purified and discharged to the standard.

Technical features

1, the material in the bag breaking process and material separation process are fully closed, and each process has a dust collection device, no dust leakage, low noise, improve the working environment of workers.

2. Only one or two people are required to place the packaging bag on the belt conveyor, which reduces the working intensity of the workers.

3, the equipment operation is simple, reliable, low failure rate, reduce the maintenance workload.

4. The equipment is specially designed, and the broken packaging bag is separated from the material, and will not be mixed into the material, nor will it be hung in the separation device.

5. After bag breaking, unloading and separation, it can be used with other conveying equipment to complete the functions of powder conveying and storage.

6, no need to adjust the equipment, you can handle different sizes of bags.

7. The equipment has dust removal function, and there is no dust flying in the process of opening the bag and pouring the material;

8. The unpacking machine can also be used as supporting equipment, which can be transported to the downstream device through the screw conveyor, the pipe chain conveyor, or the negative pressure or positive pressure conveying system of pneumatic conveying.

Note: The configuration, output, material and power of the whole set of equipment of the automatic unpacking machine have changed due to changes in material properties, usage occasions and discharging methods.

Scope of use

Automatic unpacking machine is widely used in chemical industry, petroleum, building materials, metallurgy, electric power, food, medicine, grain, environmental protection and other fields, such as nitrate lime, magnesium oxide, quartz sand, limestone, sawdust, protein powder, activated carbon, milk powder, PVC powder, fly ash, urea, clay, gypsum, cement, sewage treatment powder and so on.

Ferguson, as a research and development manufacturer of unpacking machines, also has small bag feeding stations, layer-by-layer unpacking machines, ton bag feeding stations and ton bag unpacking machines.

Related Products

Automatic unpacking of small bags

Automatic unpacking of small bags